How the UW handles extreme heat

Usually, the hottest days are over by the time school starts in late September. This year, the UW community experienced temperatures in the high-80s in mid-October.

After a blistering summer, fall temperatures have continued to break records. The Seattle area has seen the most ever October days over 70 degrees Fahrenheit and, with temperatures hitting 88 degrees on Oct. 16, the latest day ever in the year to go above 80 degrees.

Rising temperatures are affecting how we live, learn and work. With systems designed during cooler times, the University of Washington and UW Facilities are working to adapt to the new reality.

When Guarrin Sakagawa, who manages the UW’s heating, ventilation and air conditioning systems, started at the University 23 years ago, there were only two days in the 90s for the entire year. In 1989, the University’s design guide dictated that air conditioning be added only for buildings such as labs, lecture halls and libraries, he said.

In the summer of 2022, there were 13 days above 90 degrees, and all new buildings are built with air conditioning or other cooling technologies. But even that might not be enough during Seattle’s hottest days. The Seattle energy code requires buildings to be designed to cool to 75 degrees when it’s 86 degrees outside. If it's 10 degrees hotter than that, then the building will cool to only 85.

"Now we have so many days over 90 degrees. Systems aren't designed for that, and people who live here aren't designed for that either," Sakagawa said.

How campus cooling works

How campus cooling works

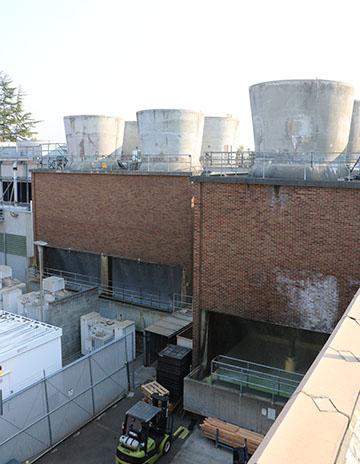

Most campus air conditioning starts at the UW Power Plant, the complex that sits on Jefferson Road just off the Burke Gilman Trail. Despite its name, the Power Plant’s main function is to provide central heating and cooling for campus. Chillers at the main plant send 12,000 tons of cold water to campus buildings for air conditioning.

Warm air extracted from the buildings then heats the water. The warm water returns to the chillers, and the heat is transferred to the cooling towers — which passersby might recognize as the artificial waterfalls visible from the Burke Gilman Trail. At the towers, the heat from the warm water evaporates.

The West Campus Utility Plant at the south end of the Ave, which the UW opened in 2017, provides an additional 4,500 tons of chilled water for air conditioning in energy-intensive research buildings in the south and west areas of campus, including the UW Medical Center. It has its own chiller and cooling towers. Some buildings also have standalone chillers and cooling towers that aren’t connected to either the Power Plant or West Campus Utility Plant.

Seattle City Light is the primary source of electricity to campus, but the two plants provide emergency power in the event of an outage.

The UW’s cooling systems work well, but they are vulnerable to failure during extreme heat. “The plant is within the specs of what it’s supposed to be able to do, but those specs were written decades ago,” said Power Plant manager Warren Midkiff.

One such failure occurred this summer when the region was in a middle of a historic heat wave.

On Tuesday, July 26, the plant was working as expected when, at 10:20 a.m., operators heard the sound of motors spinning very fast, followed by banging sounds, one after the other. Plant alarms went off, creating a pounding buzzing noise.

A Power Plant operator looked at a monitor that showed four of the seven plant chillers, and associated pumps, were no longer running. The operator turned around to find another monitor showing the water flow to campus had gone down, confirming that the chillers had failed. The plant’s chilled water capacity had plummeted from 12,000 to 4,000 tons at a time when it was needed most for air conditioning.

Daniel Higginbotham, one of the plant’s high-voltage electricians, realized that the failed chillers were all connected to the same bus, or section of the power grid, and that electrical service from Seattle City Light had failed. He switched the feed for the bus to another electrical source, and they were back up after just 15 minutes offline.

Hours later, Higginbotham and Seattle City Light staff discovered that a splice connected to the bus had failed. Air conditioning uses a lot of electricity. The higher electrical load on the splice that day, plus its advanced age, “likely stressed it enough to finally fault,” said Jeremy Park, the power systems operation manager.

In all, it took two hours for the system to return to normal. Air conditioning was cut to a few office buildings, where it was more likely that people were working from home, while most buildings experienced no interruption.

Developing a long-term strategy

Developing a long-term strategy

While the outage was brief, it was a harbinger of things to come. “We have a 24-7 crew here operating and monitoring these systems, and they are well trained and well prepared for anything. They handled this event very well,” Midkiff said. “But as the campus grows, as our electrical demand goes up, then we could continue seeing issues like this.”

The UW is developing a cooling policy to make sure campus can function as best as possible under extreme heat. The policy includes prioritizing buildings in case of a failure to minimize impact as well as being transparent on how the system is operating and putting a communication process in place.

While these measures address short-term concerns, the long-term strategy is to make the system more efficient.

As temperatures rise, UW Facilities is getting more requests from units for standalone air conditioning units and other types of cooling systems that aren’t connected to the campus plants, said David Woodson, executive director of the Campus Energy, Utilities & Operations department.

Standalone cooling systems are the least efficient use of electricity, however, said Woodson, and that could be crippling during summer when there is already so much demand on the electrical grid. In addition, maintaining hundreds of units across campus would also create an unsustainable maintenance support cost, he said.

“The solution is to increase the capacity of the central plants, because that is the most efficient use of labor resources and electricity to provide the most amount of cooling,” Woodson said. “It’s a matter of connecting more buildings and spaces to the central plants and increasing capacity of the central plants. That is the long-term strategy.”

Centralizing cooling on the plants would also aid in reducing greenhouse gas emissions, which the UW has pledged to bring down by 45% as part of its Sustainability Action Plan. While heat currently evaporates at the cooling towers, there is the potential to re-use it instead for heating purposes, like water for showers, so that less natural gas is needed. The more buildings connected to the plants, the more heat that can be used to replace natural gas.

Reducing greenhouse gas emissions also depends on using electric heat pumps instead of fossil fuels for campus heating. A more energy-efficient chilling system will free up electrical capacity that can be used for that purpose.

In addition, UW engineers are looking at alternatives to mechanical cooling. Some new University buildings feature innovative solutions, such as radiant floor cooling; green, or vegetative, roofs, which reduce roof temperatures; and designs that bring in cold air at night, which is later used to cool buildings and reduce the need for air conditioning.

‘We all play a role’

‘We all play a role’

While making cooling systems more efficient is critical to how the University withstands extreme heat, the entire UW community can also help contribute to solutions, said Joanna Pang, assistant director of Engineering Services.

“We all play a role. It's not just UW Facilities trying to find a way to save energy on campus. But it is all of us together trying to do that,” she said, noting that people can make sure to turn off lights and find other ways to conserve energy. Consolidating when people are working at home through hybrid work, using fans instead of air conditioning and allowing the set point for thermostats to go slightly higher are ways that people can contribute to reducing the electrical load.

She also challenges the community to look at cooling more “holistically.” Adding air conditioning to a building may take longer, but it’s a more efficient use of resources than adding it one space at a time.

“We want to make sure we're doing the right thing for the environment, the planet and UW,” Pang said.

In all, addressing extreme heat could cost many millions of dollars, including the cost of cooling buildings that don’t have any air conditioning and updating buildings with outdated systems. But if it’s done right, the UW will be set up for long-term success, Woodson said.

“We can see this train coming,” he said. “Our campus was designed for a mild marine climate. That's not what our future has in store for us.

“We need to adapt, otherwise we will just have a much bigger and grander problem. In responding to it in a strategic way, we can actually put infrastructure and pieces in place that help us reduce greenhouse gas emissions and help us mitigate our demand for electricity.”