Welcoming WCUP

The West Campus Utility Plant (WCUP) serves as an extension of the University’s Power Plant, providing additional cooling and emergency power to the University’s expanding collection of research buildings in the southwest corner of campus.

WHAT IT DOES

WHAT IT DOES

The University provides heating steam, chilled water and power through eight miles of distribution tunnels running beneath campus. All of that steam and chilled water, as well as emergency power, has come from the Power Plant on the eastside of campus. But that plant’s ability to provide utility and backup power service to campus has maxed out with recent campus development.

Additionally, the Power Plant only provides comfort cooling – seasonal air conditioning for human comfort during the warmer months of the year. Many newer buildings require process cooling – cooling for instrumentation in labs and server rooms needed year-round.

The West Campus Utility Plant provides campus with additional chillers and generators, enabling the dedicated crews of Facilities Services’ Campus Utilities team to better serve a growing campus. The WCUP also expands Campus Utilities’ portfolio by adding year-round process cooling capabilities.

WCUP, while connected in to the same network of utility tunnels serving all of campus, will specifically serve large research buildings in the south and west campus areas. Those buildings have more intensive research work requiring more cooling and emergency power than many other buildings across campus.

Looking ahead, west campus is the focus of the most concentrated development, as illustrated in the UW Draft 2018 Campus Master Plan. Strategically, the WCUP was built with capacity to expand, so it can meet the growing needs of a globally-ranked research University over the coming decades. As built, WCUP can provide 6 megawatts (MW) of emergency power and 4,500 tons of chilling, about half of its ultimate capacity of 12MW total and 10,500 tons of chilling. At full build out, WCUP will be able to provide more emergency power than the campus Power Plant.

“This is important to the growth of the University of Washington,” said Associate Vice President for Facilities Services Charles Kennedy. “Commissioning these new buildings depends on having the WCUP up and running.”

“As west campus grows, more and more buildings will need utility and power services,” said Campus Utilities Assistant Director Mark Kirschenbaum. “While the building itself is finished, the components inside are roughly half built out. When you walk in it’s very open inside because as the connected loads increase over the coming years we’ll add more diesel generators and chilling equipment to what’s already there.”

DESIGN-BUILD PROCESS

DESIGN-BUILD PROCESS

The WCUP was built using a highly collaborative 'progressive' design-build process, new to both the University and the state.

“Progressive design-build is where teams are selected based primarily on qualifications in lieu of a design and price,” said John Baker from Mortenson, the lead contractor on the WCUP project. “It allows the team to come on early and develop the design and construction program early alongside other project requirements, allowing the team to maximize scope and value.”

"The new delivery system was a real journey of discovery, and required more openness and trust than traditional methods. The individuals involved with this project made it work and set an important example," said Steve Harrison, the WCUP's project manager from UW Capital Planning & Development.

The building site came with challenges, being highly visible from many directions, and playing a symbolic welcoming role at a gateway to the campus area. In preparing for the project, UW's Office of the University Architect hired David Strauss of Seattle architectural firm SHKS, a UW professor of architecture, to develop design guidelines based on an analysis of the site and the desirable characteristics of a building there to serve as a gateway structure and public landmark. The guidelines help to communicate, through the quality and care of its design and siting, the University's respect for the broader community.

“This site was identified by the University for a number of reasons,” said Anton Dekom, an architect from Miller-Hull on the WCUP project. “The most significant is that it provides easy, direct access to the distribution tunnels running beneath campus, but we were also cognizant that this location is on one of campus’ busiest entrances, along 15th Ave. NE and NE Pacific St.”

“Being a utility plant, this building requires extreme reliability in operations, but its location also requires architectural excellence,” said Baker. “Those two interests were not always in alignment at the beginning, but at the end of the day I think we achieved a truly amazing outcome.”

Because of that front-porch location, architects from Miller-Hull decided to take the opportunity to “make the invisible visible” – trying to get the campus community to think about the infrastructure needed to power and supply campus.

“When people notice infrastructure facilities, such as power plants and utility plants, we can use that as a way to build awareness of these as critical resources for how you go about your daily life, how you use power or manage your water use in a responsible away,” said Scott Wolf, another architect from Miller-Hull on the WCUP project.

“A lot of infrastructure projects are taken for granted, tucked away where we don’t really see them,” said Dekom. “By putting this plant in the middle of campus where it’s quite visible, we wanted to put all of that equipment on display. I don’t know of anywhere else in Seattle where you can walk up to a building and see this kind of industrial scale equipment on display. I think it goes a long way in educating the public about the importance of infrastructure.”

The plant’s design helps to highlight the services it provides in many ways. With large glass windows overlooking University Way NE, any passerby can look inside to see three enormous chillers, providing campus with 1,500 tons of chilling each, and a show of colorful pipes and valves.

The plant’s most visible feature is a softly glowing wall surrounding the roof. The glow makes the building visible at night from as far as I-5, like a beacon marking the campus. 64 LED lights brighten up the screen wall with varying levels of intensity. The lights shift subtly over periods of two and eight seconds, like fireflies in a jar.

“The screen wall is really meant to provide some subtle activity to the façade of the building, and mitigate noise from the equipment on the roof. The façade helps to carry out this magnet and portal idea that carried us through the design of the building. The screen is the magnet, drawing people to the building, and the windows are a portal into the process behind-the-scenes,” said Wolf.

Assistant Director for Campus Utilities Mark Kirschenbaum leads a tour on the roof of the new West Campus Utility Plant.

SUSTAINABILITY

SUSTAINABILITY

The building design exemplifies the University's core value of environmental sustainability. Centralized utility services, like those provided by the new WCUP, allows the University to better provide utility to its buildings in a cost-effective and efficient way, allowing the UW to better manage its carbon footprint.

“Centralized services like the Power Plant and WCUP allow for much more reliable services. I know that doesn’t sound very exciting, but when you distribute everything to the individual buildings it’s a large challenge, especially for the University, to keep that equipment running at optimum efficiency and reliability,” said Kirschenbaum.

WCUP continually monitors the air temperature outside, providing the cooling classrooms and labs need, without wasting energy. Chillers and generators inside the building are fully automated, so the building doesn’t need to be staffed 24/7 like the Power Plant, although it will be monitored by control operators at the Power Plant.

“Think of it as a large air conditioner, but it’s not stuck on just one setting relying on someone to come in and change it when the weather changes. The WCUP reads outside air temperatures and raises and lowers itself to fit the exact conditions of the moment. It’s complicated, it’s not unique, but it’s unique to us,” said Kirschenbaum. “It’s a new thing for us on this scale especially. There are buildings in downtown Seattle that may do the same thing, but to do it on a district scale like we’re doing with multiple buildings being impacted and chilled water distributed across campus is pretty exciting.”

Miller-Hull expects the building to be certified as Envision silver or gold, a ranking similar to the more well-known LEED system. LEED is for buildings with occupants, while Envision is a green certification for sustainable infrastructure projects.

“This Envision certification will be a first for both the University and for Envision,” said Wolf. “The West Campus Utility Plant will be the first Envision-certified higher education project in the country.”

The building and site work together to handle stormwater, taking all of the rain that lands on the roof and redirecting it to planter boxes along the sidewalk, contributing to water quality and diminishing erosion.

An interpretive element on the University Way side of the building helps to communicate the University's sustainability story.

Read more about the interpretive element on the UW Sustainability blog.

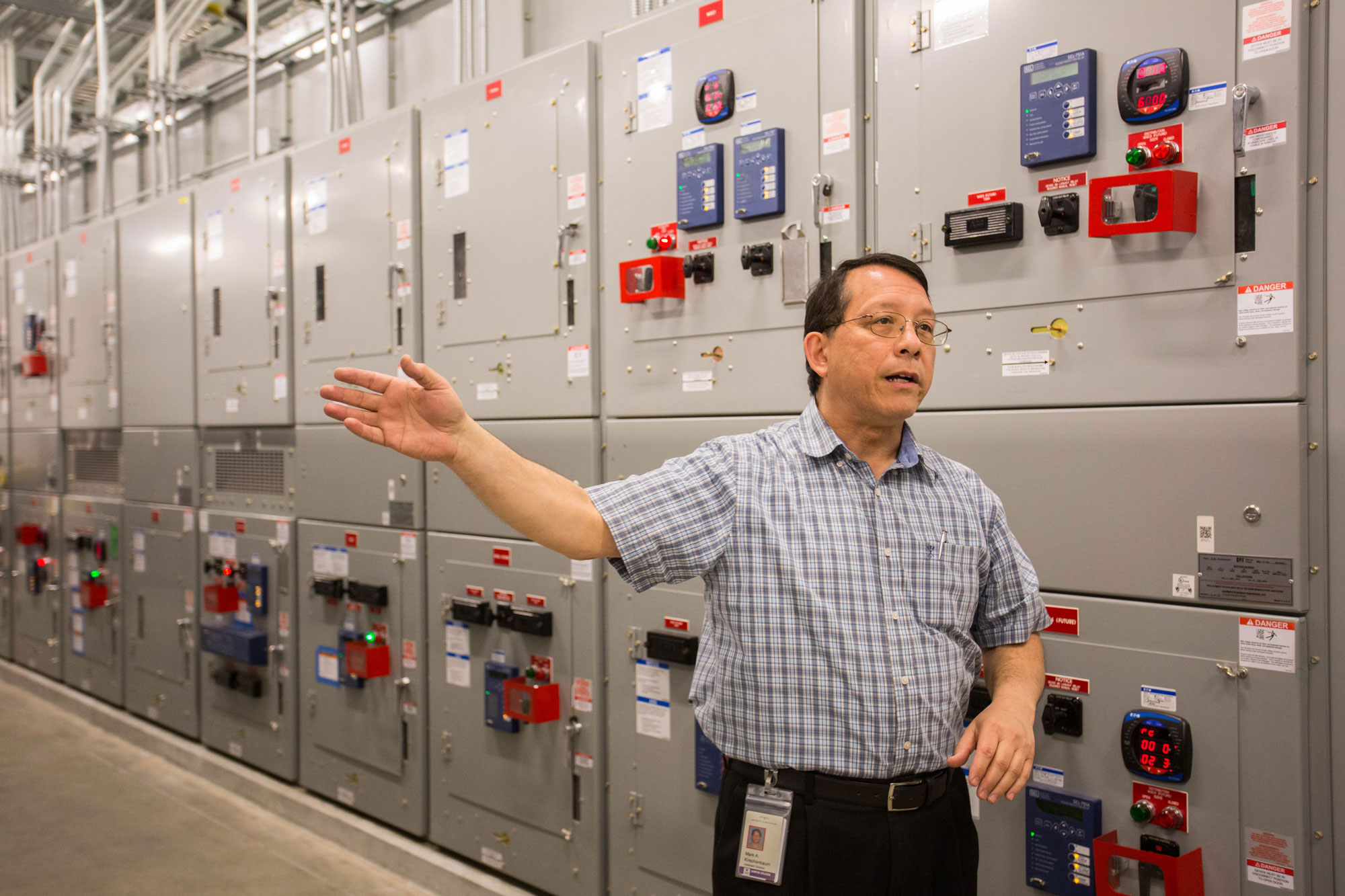

Assistant Director for Campus Utilities Mark Kirschenbaum leads a tour near the West Campus Utility Plant's new high voltage electrical panels. The plant provides emergency power for campus through its three diesel generators.

COLLABORATION

COLLABORATION

“This was an extremely collaborative process with all of our partners here at the University as well as those in the construction community,” said Kennedy. “Ultimately, that collaboration led to the successful completion of this project.”

Ultimately, the project was completed on schedule and on budget.

The WCUP team includes the following people and firms:

University of Washington

Facilities Services

John Chapman, Executive Director, Campus Engineering & Operations

Mark Kirschenbaum, Assistant Director, Campus Utilities

Jeremy Park, Power Systems Operations Manager

Joe Cook, Facilities Engineer, Campus Engineering

Capital Planning & Development

Steve Harrison, Project Manager

Rebecca Barnes, University Architect, Associate Vice Provost for Campus Planning

Kristine Kenney, University Landscape Architect, Director of Campus Design & Planning

Bob Puzauskie, Senior Planner

UW Sustainability

Claudia Frere-Anderson, Director

Daimon Eklund, Communications Coordinator

Marilyn Ostergren, Renewable Energy Liaison

Design-build team

Mortenson Construction, contractor

Miller-Hull, architects

Arup, engineers

KPFF, engineers

GGN, landscape architect

McKinstry, engineers

Cochran, engineers