Granite got you down?

Andy Schlais from Facilities Maintenance and Construction installs a PaperStone counter top in the Health Sciences Building in Seattle, Wash. on Jan. 13, 2016.

Down in the H-wing of the Health Sciences Building, one lucky lab has a new replacement lab bench, and it’s made out of 100% recycled paper.

Facilities Maintenance and Construction is slowly integrating a new, sustainable material into their projects: PaperStone.

PaperStone products are made of Forest Stewardship Council-certified 100% post-consumer recycled paper, treated with a resin, and heated and compressed until it becomes rock-solid.

The Forest Stewardship Council, a non-profit organization, gives sustainable products a “stamp of approval” if the product meets certain sustainable criteria. According to the FSC, in order for a product to garner the FSC labeling, the forest must be, “managed in an environmentally appropriate, socially beneficial and economically viable manner.”

PaperStone can be used for counter tops, signs, plaques, furniture, cabinets, and other items that need solid surface material.

Eric Dauplaise, assistant director for Facilities Construction, heard about the product in September 2015 and set up a meeting with the distributor to discuss the pros and cons of the product.

When FMC was first beginning to determine whether to use PaperStone products for their projects, they had to determine if the product had long-term value. According to Ed McKinley, the shop 54 finish carpentry lead with FMC, the team considered the cost of the product, the sustainability of the material, the durability, and the effort needed for employees to install and manipulate the material.

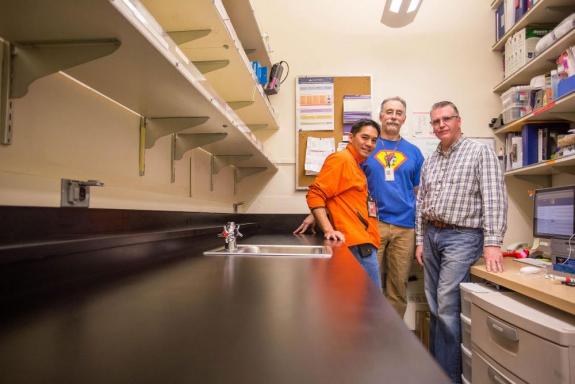

The lab bench replacement is one of the first projects that has used PaperStone. The install took place in early January. Andy Schlais and Doug Parshall from FMC worked to fit the counter top. Schlais said the previous counter had severe scratches and pitting, and needed to be replaced because of sanitization concerns.

The PaperStone shelves arrived pre-cut, although the team made additional cuts in the FMC shop. According to Schlais, the products wear through the cutting blades quicker than their wood products.

“The thing that’s attractive about this product is that, if it’s a replacement for stone counter tops, it’s easier to cut and easier to customize. We can put sink holes in, for example, granite, but it is a long process and the equipment is expensive. PaperStone can be cut in our shop,” Schlais said.

After the installation was completed, Lenny Lunasco, a plumber with FMC, was ready to go reinstalling the plumbing fixtures.

Dauplaise said it is hard to tell of the pros of the product so far, but in their initial assessment, they learned that the PaperStone products are able to handle high heat, and have a sensitivity to chemicals that is good, if not better, than traditional countertops like granite. According to Dauplaise, the product is better than granite, and has about an average scratch resistance.

“We’re trying to move towards a more sustainable product that has the durability we’re looking for,” Dauplaise said.

It’s an added bonus the manufacturer and distributer are located in-state. For previous projects, the FMC used to have to wait for products to be delivered from the Midwest. PaperStone projects have potential for a quicker turn-around.

The finish carpentry shop has installed a few new countertops thus far. The team has installed new grey countertops in the kitchen in the Child Care Center, and a lighter countertop in the break room of Plant Services.

Currently, the team is working on designing a lab bench in the Physics-Astronomy Building.