Meeting our goals

“You know, I really don’t think I’m the person to talk to about this,” said Facilities Maintenance & Construction Director Damon Fetters. “This is all the work of employees coming together to make safety a part of the culture and a part of the work that they do.”

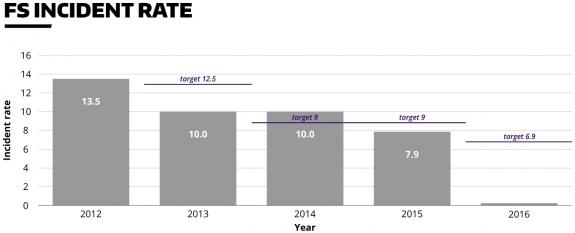

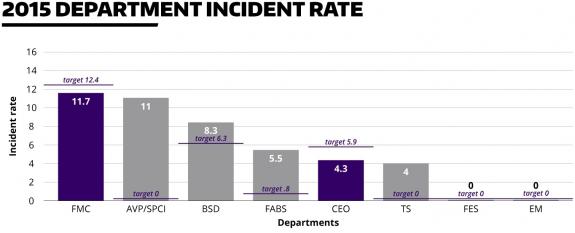

Facilities Services set a record safety incident rate of 7.9 for 2015, well under the target of 9. Facilities Maintenance & Construction and Campus Engineering & Operations helped lead the way by coming in significantly below target, and Facilities Employee Services and Emergency Management met their 0-incident targets.

“Damon and FS Safety Manager Tracey [Mosier] told us what our goals were for this last year, and the FMC safety team looked at how we could achieve that,” said Facilities Construction’s Carpentry Lead Mark Pekarek. “We’re trying to have our employees be more proactive about safety, assessing their scope of work ahead of time and thinking through everything before they begin the work.”

For FMC, safety has really become a part of their work culture. In May the department will be holding an all-hands meeting entirely focused on safety.

“Complacency will get you killed,” said Pekarek. “If you jump on that ladder without fully inspecting it, you’re really putting yourself at risk; especially if the ladder isn’t tall enough for the work you’re doing.”

The cultural shift comes alongside a number of programs taken on by FS Safety in the last year.

“We launched the Stop Work program last year, and I’m sure that’s helped introduce conversations about safety in the field where conversations might not have taken place before,” said Safety Manager Tracey Mosier. “We also provided support to Building Services in tackling stair-related injuries with a Lean launch last year, held our first ever fall-prevention open house, and brought Barbara Brown onto our team, which has allowed us to be more responsive in our training needs.”

For the next year, target incidents have been set even lower at 6.9, but Mosier is excited about the new programs coming up to help FS reach its new goal.

“We have a personal protective equipment (PPE) open house on April 20, and the results of Building Services’ SHIP grant coming in 2016,” said Mosier.

Funding from the grant allowed BSD to take a hard look at the tasks that cause custodians the most discomfort, and are the leading cause of work-related injuries. The result will be new short-term and long-term solutions that prevent discomfort and injuries to Building Services employees.

Additionally, FS Safety will begin implementing its new Hazard Communications training materials this year, borne out of a Lean team launched in 2015. The team also hopes to launch a new hoisting and rigging program, and with the help of Meredith Brothers in Facilities Maintenance & Construction, a refresher course on erecting scaffolding.

“A lot of our employees have been around for some time, and a refresher course always helps keep safety at the forefront of their minds,” said Mosier. “Our employees are also really great at helping each other better understand training, because they have so much experience.”

WHO IS FS SAFETY?

WHO IS FS SAFETY?

FS Safety is composed of FS Safety Manager Tracey Mosier, Safety Analyst Chris Pennington, and Health and Safety Trainer/Specialist Barbara Brown.

They provide safety support and expertise to all FS departments and workgroups. Though they work closely with our friends at EH&S, they are FS employees, not a part of EH&S!

Correction: an earlier version of this article implied the FS Safety team would create the scaffolding class. They would like to update it to give credit where credit is due: FMC’s Meredith Brothers, who has worked hard to help make this class happen.